Wood Plastic Composite (WPC) is fast emerging as a smart, sustainable, and economical choice for various modern consumer applications. It is the go-to material of choice for consumer goods, furniture, decking, fencing, and several automotive applications. Among its many modern use-cases, construction applications are surging WPC demand globally.

Builders and city planners are seeking construction materials that meet both functional requirements as well as sustainability norms. Wood plastic composite, powered by recent innovations, can aptly meet the core aspects of sustainable development such as resource conservation, energy conservation, circular economy, environmental protection, emission reduction, and low-carbon economy.

Replacement of wood with WPC in several key applications is fueling the global market. The global market value of wood plastic composite is estimated to grow at a CAGR of 8.57% during 2020-2027 to hit USD 9.03 billion by 2027, as per a report by Fortune Business Insights.

Why is WPC a Desirable Construction Material?

Wood plastic composite is created from a unique blend plastic fibers and natural wood. Bamboo, pulp, sawdust, and other woodworking materials are combined with plastic powder to produce WPC. What’s most remarkable about the product is that it can be entirely created from recycled materials. In addition, used WPC can be further processed and recycled to manufacture new WPC, making it 100% recyclable.

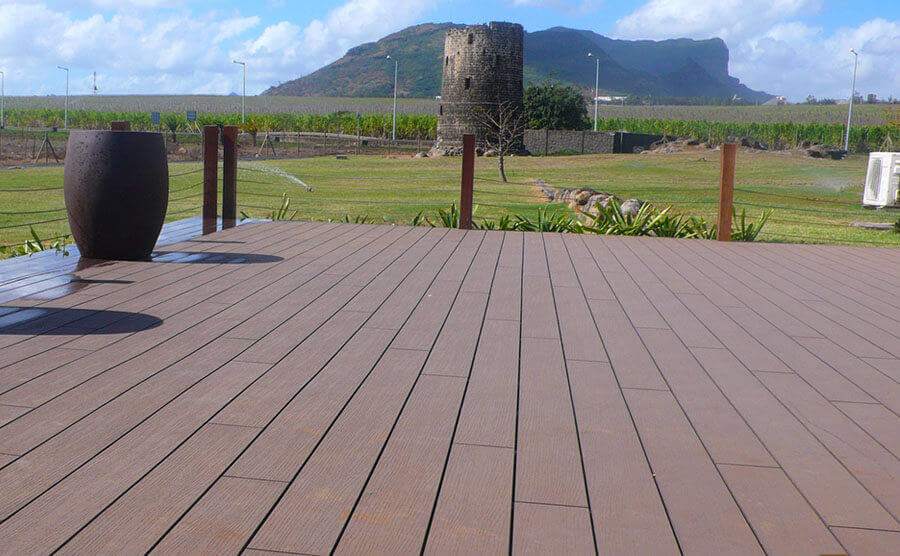

Modern construction requires materials that are durable, reliable, and versatile. WPC is widely preferred in various applications as it can be easily molded to nearly any shape and size. Furthermore, it can be colored or dyed to suit almost any design idea. These properties of the material offer homeowners better flexibility in terms of design and customization.

From a functional standpoint, wood plastic composites are highly durable due to their moisture-resistant and rot-resistant characteristics. On account of these properties, the material lasts aesthetically as well as integrally longer than normal wood. Decking, fencing, sliding, and furniture are currently among the top application areas of such composites and new use-cases are constantly emerging.

Continuous residential and commercial expansion globally and a notable uptick in home renovation are likely to propel the market of wood plastic composite in the near future.

How Has COVID-19 Impacted WPC Demand & Consumption Trends?

Since the outbreak of COVID-19, construction activity experienced a steep decline and constant disruptions. With strict lockdowns and transportation restrictions, the movement of goods and labor was halted, leading to massive demand-supply gaps. In addition, supply chain uncertainty created additional challenges for building & construction companies. As a result, ongoing construction projects were put on hold, while upcoming projects were delayed or cancelled altogether. Thus, WPC demand experienced notable decline amid the pandemic.

Another key factor that hampered the growth of the WPC industry, particularly during the initial few months of the pandemic, was diminished consumer spending on home renovation and home décor. While recent trends show that consumers have been spending heavily on home interior, investments declined significantly at the start of the pandemic as the majority of consumers prioritized essential commodities. However, as the pandemic progressed, home renovation spending exhibited signs of recovery.

Over the next few years, the wood plastic composite industry is set to benefit significantly from the global infrastructure boom and the rise in home renovation activity.

Future of the WPC Industry

Wood plastic composite materials are among the fastest-growing plastic additives in the world today. As technology and material science advance, new applications of these composites are continuously being realized. From home furniture and kitchen accessories to vehicle interiors and car speakers, these high-performance materials are providing sustainability, longevity, and cost-savings across new consumer sectors.

High initial cost remains a major factor limiting WPC adoption. The buying cost of plastic wood composites is higher than that of plastic and wood. Therefore, many countries rich in wood production still prefer pure wood over WPC. In addition, since composites are a blend of plastics and wood fibers and not completely pure, thermal expansion of materials and shrinkage of plastic are key factors to be considered at the time of installation. Therefore, these factors could boost the demand for product alternatives.

However, the market players of are constantly investing in R&D to bring novel solutions to the market. Expanding research and innovation in the field will create lucrative opportunities for the market growth over the forecast period.

About the author

Hrishikesh Kadam is a graduate in Electronics & Telecommunication Engineering and is passionate about penning down quality content for a range of domains. Besides writing, he enjoys Netflix, good music, and working out.