The mere thought of a dental drill can send shivers down the spine of many. That high-pitched whine, the sensation of vibration – it’s an experience few look forward to. Yet, this often-maligned instrument is a cornerstone of modern dentistry, allowing for precise and effective treatment of tooth decay and other dental issues. What many don’t realize is that the journey of the dental drill is a fascinating story of innovation, spanning millennia from rudimentary tools to the sophisticated high-speed devices used today. It’s a testament to human ingenuity in the face of a universal problem: aching teeth.

Echoes from Antiquity: The First Attempts

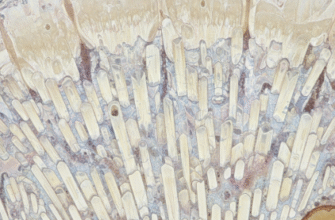

The desire to alleviate dental pain and repair damaged teeth is as old as civilization itself. Archaeological evidence suggests that rudimentary forms of dental intervention were practiced long before what we’d recognize as a “drill” came into existence. As far back as 7000 BCE, in the Indus Valley Civilization, evidence has been found of teeth being drilled, likely with flint-tipped instruments rotated by hand. These early attempts were undoubtedly slow, painful, and probably more about releasing pressure or removing grossly decayed material than precise cavity preparation.

The first mechanical device that bears a resemblance to a drill in principle was the bow drill. This ancient tool, used for thousands of years for starting fires and drilling holes in wood or stone, was adapted by some cultures for dental purposes. A cord would be wrapped around a spindle (the drill bit), and a bow moved back and forth to create a rotational motion. While an improvement over hand-twisting, it was still incredibly slow, offered poor control, and relied entirely on the operator’s strength and skill. Imagine the discomfort and the time it would take to address even a small area of decay with such a method!

The Stirrings of Mechanical Ingenuity: 18th and 19th Centuries

The 18th century, often hailed as the Age of Enlightenment, brought significant advancements in many scientific fields, including dentistry. Pierre Fauchard, the “father of modern dentistry,” meticulously documented dental practices but didn’t invent a drill himself. However, his work laid the groundwork for a more scientific approach to dental care, highlighting the need for better tools.

The first notable step towards a dedicated mechanical dental drill came from an unexpected source. John Greenwood, who served as George Washington’s dentist, adapted his mother’s foot-powered spinning wheel in 1790 to rotate a drill. This “dental foot engine” allowed for more continuous rotation than a bow drill, but it was still cumbersome and offered limited speed and torque.

Throughout the 19th century, inventors tinkered with various mechanisms. Clockwork drills, powered by wound springs, made a brief appearance but were not widely adopted due to their limited power and running time. The real breakthrough in this era came in 1871 when American dentist James Beall Morrison patented a pedal-operated dental engine. This device, much like an old foot-pedal sewing machine, used a cord and pulley system driven by the operator’s foot. It could achieve speeds of up to 2,000 revolutions per minute (rpm), a significant improvement, though still a far cry from today’s standards. Morrison’s invention was a commercial success and marked a turning point in making mechanical drilling a more practical reality in dental offices.

James Beall Morrison’s 1871 invention of the foot-pedal dental engine was a pivotal moment. It provided dentists with a relatively consistent and hands-free power source for their drills. This allowed for more controlled and efficient removal of tooth decay than previously possible with hand-cranked or bow drills, significantly advancing operative dentistry.

The Electric Spark

The late 19th century was abuzz with electrical innovation, and dentistry was not left behind. In 1875, another American dentist, George F. Green, patented the first electric dental drill. This was a monumental leap forward, as electric motors offered the potential for much higher speeds and more consistent power than any manual or foot-powered device. Early electric drills, however, were bulky, often tethered by unwieldy power supplies, and the motors themselves were not always reliable. Speed was still relatively low by modern comparisons, and issues like vibration and heat generation at the bur tip remained significant challenges for both patient comfort and tooth health.

Despite these initial hurdles, the promise of electricity was undeniable. Over the subsequent decades, electric motors became smaller, more powerful, and more refined. Dental units began to integrate these electric drills, making them a standard fixture in dental practices by the early 20th century. However, these were typically “slow-speed” engines, operating in the range of a few thousand rpm up to perhaps 30,000 rpm with belt-driven handpieces. While a vast improvement, the quest for even greater speed and efficiency was far from over.

The High-Speed Revolution: Air Power Takes Over

The mid-20th century witnessed the most transformative development in the history of the dental drill: the advent of the high-speed air-turbine handpiece. The limitations of electric motors and belt-driven systems were becoming apparent. Belts could slip, bearings would wear, and achieving truly high rotational speeds efficiently was a persistent engineering challenge. The breakthrough came not from electricity, but from compressed air.

In 1957, Dr. John Borden introduced the Airotor. This revolutionary handpiece used compressed air to spin a small turbine located directly within the head of the handpiece. This design eliminated the need for complex belts and gears linking a distant motor to the bur. The Airotor could achieve astonishing speeds, initially around 100,000 rpm, but quickly escalating to 200,000, 300,000, and even 400,000 rpm or more in subsequent designs by various manufacturers.

The impact of these ultra-high speeds was profound:

- Reduced Pressure: Dentists no longer needed to apply significant force. The high speed allowed the bur to cut through enamel and dentin with much lighter pressure, akin to a paintbrush.

- Less Vibration (at the tooth): While the high-pitched whine became iconic, the actual vibration transmitted to the tooth was often less perceptible and less damaging than that from slower, gear-driven handpieces that “chattered” more.

- Faster Procedures: Cavity preparations that once took considerable time could now be completed much more quickly, benefiting both patient and dentist.

- Improved Precision: The smoother cutting action allowed for more precise and conservative tooth preparation.

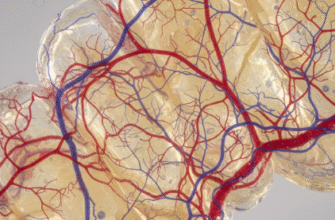

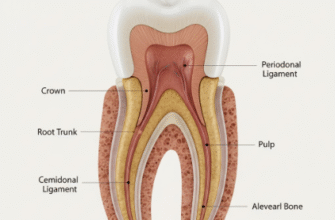

This era also saw the integration of crucial supporting technologies. Water spray, directed at the bur tip, became essential to cool the tooth and the bur, preventing heat damage to the pulp and clearing debris. Fiber optic illumination, integrated into the handpiece itself, provided direct lighting of the operating field, drastically improving visibility for the dentist.

The introduction of the air-turbine high-speed handpiece by Dr. John Borden in 1957 fundamentally changed dental procedures. While dramatically increasing cutting efficiency and reducing procedure time, the immense heat generated necessitated the simultaneous development and adoption of effective water cooling systems. Without this cooling, the high speeds could have caused significant thermal damage to tooth pulp.

Refinements and Modern Iterations

Since the advent of the air turbine, development hasn’t stood still. Handpiece design has continued to evolve with a focus on ergonomics, durability, and further reducing noise and vibration. Key advancements include:

- Ceramic Bearings: These offer smoother operation, longer life, and can withstand higher sterilization temperatures compared to traditional steel bearings.

- Improved Turbine Design: More efficient turbines provide greater torque, meaning the drill is less likely to stall under pressure.

- Quick-Connect Couplings: Allowing for easier changing and sterilization of handpieces.

- Anti-Retraction Valves: Enhancing infection control by preventing suck-back of oral fluids into the handpiece and airlines.

Interestingly, while air turbines remain the workhorse for many high-speed applications, modern electric high-speed handpieces have seen a resurgence and significant technological advancement. These contemporary electric systems offer variable speed control with consistently high torque across the entire speed range, which some practitioners prefer for certain procedures. They are often quieter than air turbines and can offer more precise control, especially at the lower end of their speed range. These are not the bulky electric motors of the early 20th century but sophisticated, compact systems.

Beyond the Bur: The Continuing Evolution

Today’s dental drill is a marvel of engineering, a far cry from the flint tips and foot engines of the past. It enables dentists to perform intricate work with a level of precision and relative comfort that would have been unimaginable to their predecessors. The evolution has been driven by a relentless pursuit of efficiency, patient comfort, and improved clinical outcomes.

While the high-speed handpiece remains central, research continues into alternative methods for tooth preparation, such as dental lasers and air abrasion systems. However, for many common restorative procedures, the refined dental drill, whether air-driven or electric, continues to be an indispensable tool. Its journey from a simple bow to a sophisticated, high-velocity instrument mirrors the broader progress of dental science itself, constantly striving to make dental care more effective and less intimidating. The next time you hear that familiar sound, perhaps you’ll appreciate the centuries of innovation that led to the remarkably advanced tool working to restore your smile.